Zhejiang Allwell Intelligent Technology Co.,Ltd

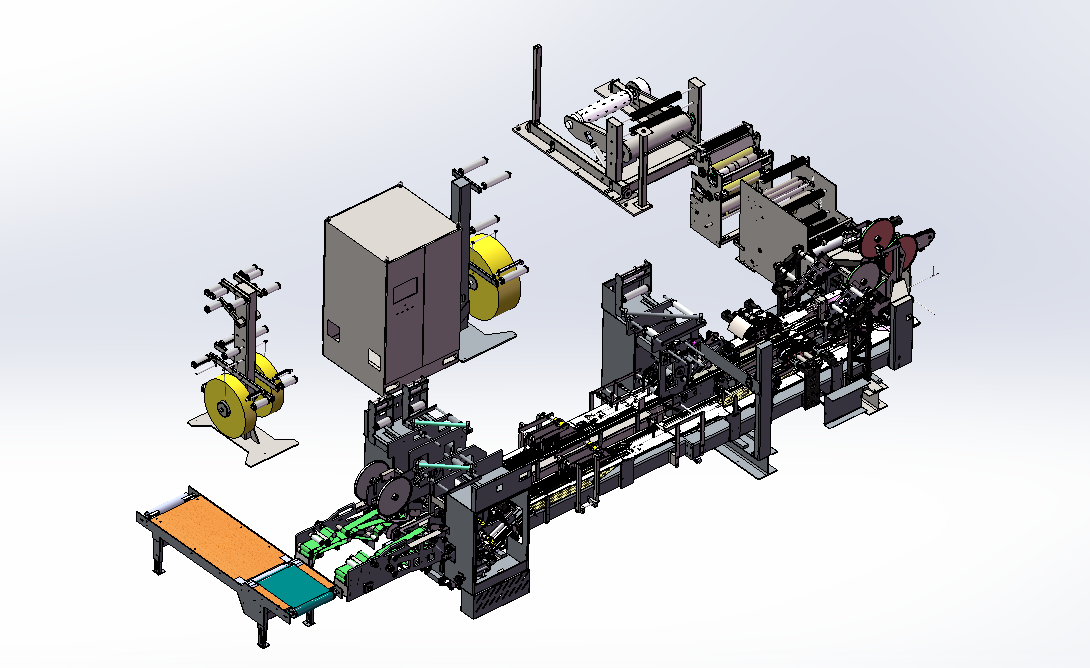

Zhejiang Allwell Intelligent Technology Co., Ltd. is china Leading

and professional manufacturer for non woven bag making

machines, nonwoven printing machines, soft handle sealing machines

and relevant equipment in 15 years. In year 2019 ,we start our

paper bag machine production lines, meanwhiile united and

import newest techenology with Japan famous brand Newport shanghai.

Our company has an area of 130,000 square meters and 400 on-the-job

employees. Oyang brand is very famous in global market, we have 120+hundred

clients all over the world, and our nonwoven bag machine market

share more than 85%. Ounuo Invest USD200 million imported

Japan MAZAK,OKUMA high-precision CNC machining center, make

high quality spare parts & ensure whole machine stable usage

longtime.

Our strong and professional sales team will provide you with

details of machine introduction. According to each customer's

different requests, we provide individual and special machine

solutions.

Our goal is to serve every customer with 100% confidence and

passion.

We are expecting your kind attention. and Welcome to contact

us ! Whatsapp: 008615257791882