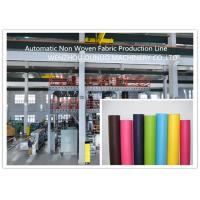

Medical Non Woven Fabric Production Line Recycle extruder For bag

General Information For Nonwoven Machine

| Model No. | ONL-1600SSS | ONL-2400SSS | ONL-3200SSS |

| Working Width | 1600mm | 2400mm | 3200mm |

| Fabric GSM | 15~250 | 15~250 | 10~250 |

| Power Input | 600KVA | 800KVA | 1000KVA |

| Consumption | 400KW | 600KW | 800KW |

| Annual Output | 3500T | 5000T | 6500T |

| Embossing Pattern | Diamond, Oval |

| Fineness | 1.5~2.5dtex

|

Parts of spunbonded nonwoven fabric production line:

Recycle extruder---->Main extruder---->Filter---->Metering

pump---->Monomer suction device--->Spinning

box---->Quenching air chamber---->Stretching

device---->Web

former---->Calender---->Winder---->Slitter

Spun-laid process and technical flow chart:

Additive(Recycling offcut fabric)---->Raw

material---->Melting---->Filtering---->Measuring

---->Spinning---->Cooling---->Stretching---->Web

forming---->Calendering---->Winding---->

Cutting---->Final product

Main Feature

A. Short technological process and high production efficiency,

B. The whole process from charging materials to fabric output is

controlled automatically. The AC frequency conversion technology

(which is more energy-saving) and touch screen control have been

adopted. The technology possesses advantages of reasonable

structure with space- saving style , high working performance, low

production consumption, easy operation, less operating troubles,

etc.

C. Controlled by PLC operated by touch screen .

E.Nonwoven fabric usage:

(1) Medical and health usage:operation suit,garment,face

mask,diaper,sanitary napkin,disposable hygiene product.etc;

(2) Home decoration:shopping bag,wall covering fabric,table

cloth,bed sheet,bedspread.etc;

(3) Lining for clothes or shoes:lining,adhesive interlining,shoe

lining.etc;

(4) Agricultural usage:Protection cover,nursery cover.etc;